This project proposes a solution to this issue through a cost-effective and space-efficient drill press adapter. This adapter is designed to eliminate the problem of imprecise vertical drilling when using a handheld drill.

The drill press adapter will feature a standalone, bolted frame designed to occupy minimal space. A lead screw mechanism will control the vertical movement of the drill, while the drill itself will be securely held in place to ensure user safety. The objective is to create an adapter capable of handling a wide range of materials, including materials such as 1018 stainless steel, provided the user employs appropriate drill bits for the application.

The mechanism responsible for raising and lowering the drill will utilize a lead screw in combination with a linear guide to ensure precise and stable vertical movement during drilling operations. A hand crank was incorporated in the design to allow the user to raise and lower the drill at their discretion

The handheld drill holster is designed to be compatible with a wide range of handheld drills from leading manufacturers such as Milwaukee and DeWalt. The holster will feature a form-fitting cavity to securely cradle the drill, ensuring a stable and precise fit. To prevent any movement during operation and to promote user safety, the drill will be firmly secured using a clamping collar.

What is this project?

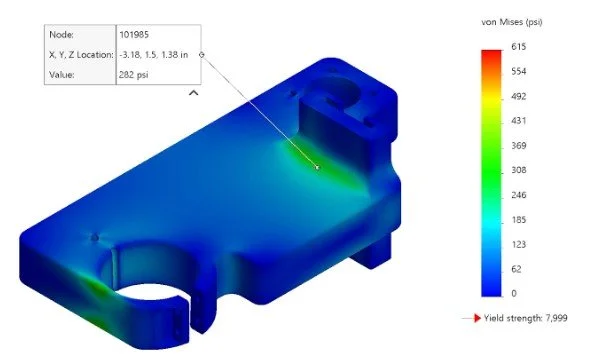

In addition to the design work, all major frame components were analyzed for static and fatigue failure. Hand calculations were compared with FEA results to validate the analysis. Further hand analyses were performed on critical connections, including calculations to assess the potential failure of specific bolts and screws within the design.